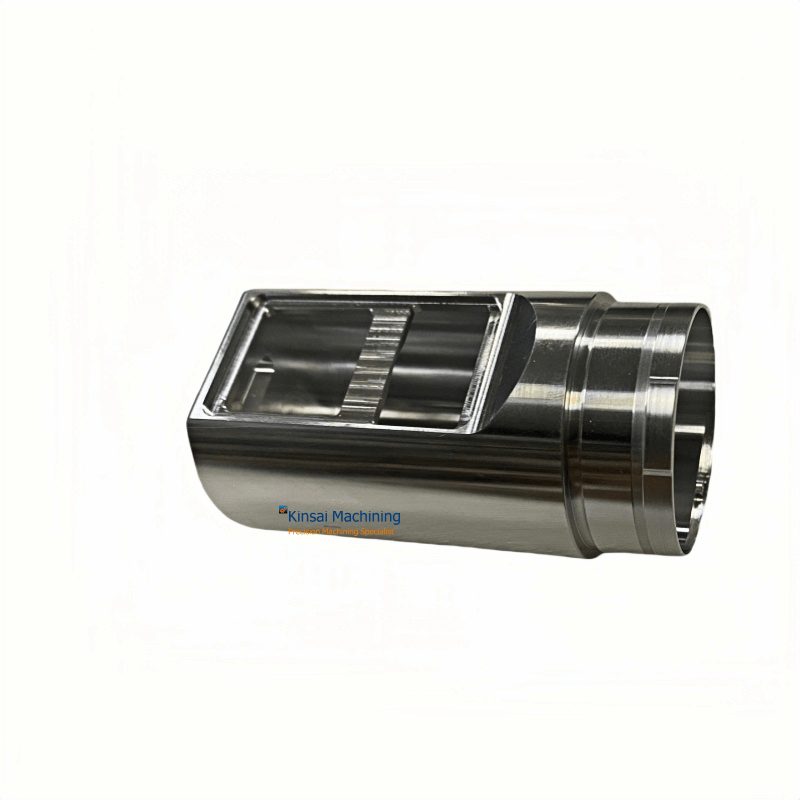

Kinsai Machining is a leading China-based manufacturer specializing in high-precision CNC turning services. We deliver top-quality, custom CNC-turned parts for global clients across various industries.

What is CNC Turning?

CNC turning is a subtractive manufacturing process that utilizes computer numerical control (CNC) machines to shape and size raw materials into precise components. A rotating workpiece, coupled with controlled cutting tools, creates desired geometric shapes based on digital specifications.

Benefits of CNC Turning:

- High Precision: Kinsai’s advanced CNC turning machines guarantee consistent accuracy and meet strict concentricity requirements. This translates to high-performing parts and reduced production costs for you.

- Efficiency and Speed: Compared to traditional methods, CNC turning offers faster production times with stable performance. Larger cutting feeds and easy operation minimize turnaround times.

- Versatility for Diverse Needs: CNC turning excels at producing parts in various materials, including metals (steel, aluminum, brass) and even non-metals (plastics, wood). It accommodates both rapid prototyping and mass production, making it a flexible solution for your project.

- Superior Surface Quality: CNC turning delivers exceptional surface finishes, ideal for components requiring high precision and smooth textures.

Kinsai’s CNC Turning Capabilities:

- Wide Material Range: We work with aluminum, brass, stainless steel, Delrin, PETP, PEEK, and more.

- Prototype and Volume Manufacturing: From single prototypes to large-scale production runs, we cater to your specific needs.

- Global Customer Support: Our sales engineer team provides prompt communication and comprehensive support throughout your project.

Ready to Get Started?

Contact Kinsai Machining today for reliable and efficient CNC turning services in China. Email your 2D or 3D drawings to sales@kinsaimachining.com for a free quote within 24 hours.